Heat Studies involve a detailed analysis of the thermal conditions in pharmaceutical facilities, focusing on buildings and equipment. Our engineers are experts in heat transfer principles, thermodynamics, and computational modelling. They conduct thorough heat load assessments to determine the best insulation, ventilation, and HVAC system designs for pharmaceutical facilities. This includes calculating heating and cooling loads, determining temperature gradients, and identifying potential heat sources or sinks.

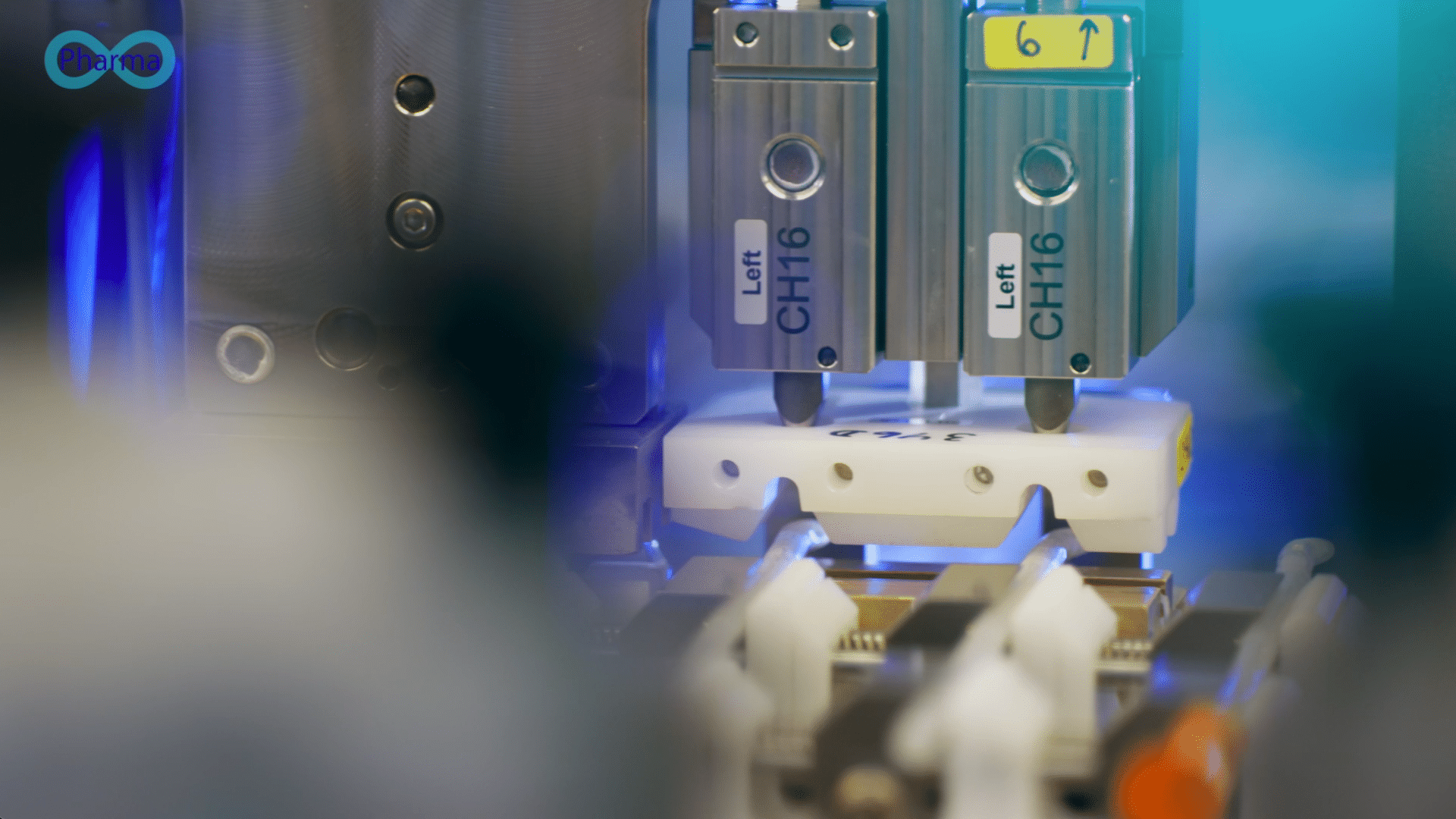

Our specialists are also skilled in the thermal characterization of pharmaceutical equipment. They carry out in-depth assessments of equipment heat generation, conduction, and dissipation. Using advanced analytical tools, they model heat dispersion patterns to ensure equipment operates within the required temperature ranges, which is crucial for maintaining product integrity.

In addition, our engineers are fully aware of the regulatory frameworks and standards that govern Heat Studies in pharmaceutical manufacturing. They ensure that thermal assessments align with industry-specific guidelines, providing our clients with increased efficiency and strict adherence to quality and safety standards.

Our engineers also have practical experience in conducting Heat Studies across a wide range of pharmaceutical facilities. This includes both traditional API manufacturing processes and new technologies in medical device production, ensuring a comprehensive and adaptable approach to thermal management.

In conclusion, our consultancy offers unmatched expertise in Heat Studies of buildings and equipment, thanks to the exceptional skills of our engineers. We help pharmaceutical manufacturers and medical device developers manage their thermal conditions accurately and effectively, leading to the production of top-quality therapeutics and medical devices, and ultimately improving patient care.

We strive to implement simple and operational solutions, and can support the implementation of procedures and training activities that ensure compliance with existing authority requirements and inspection readiness.

We use cookies to optimize our website and our service.