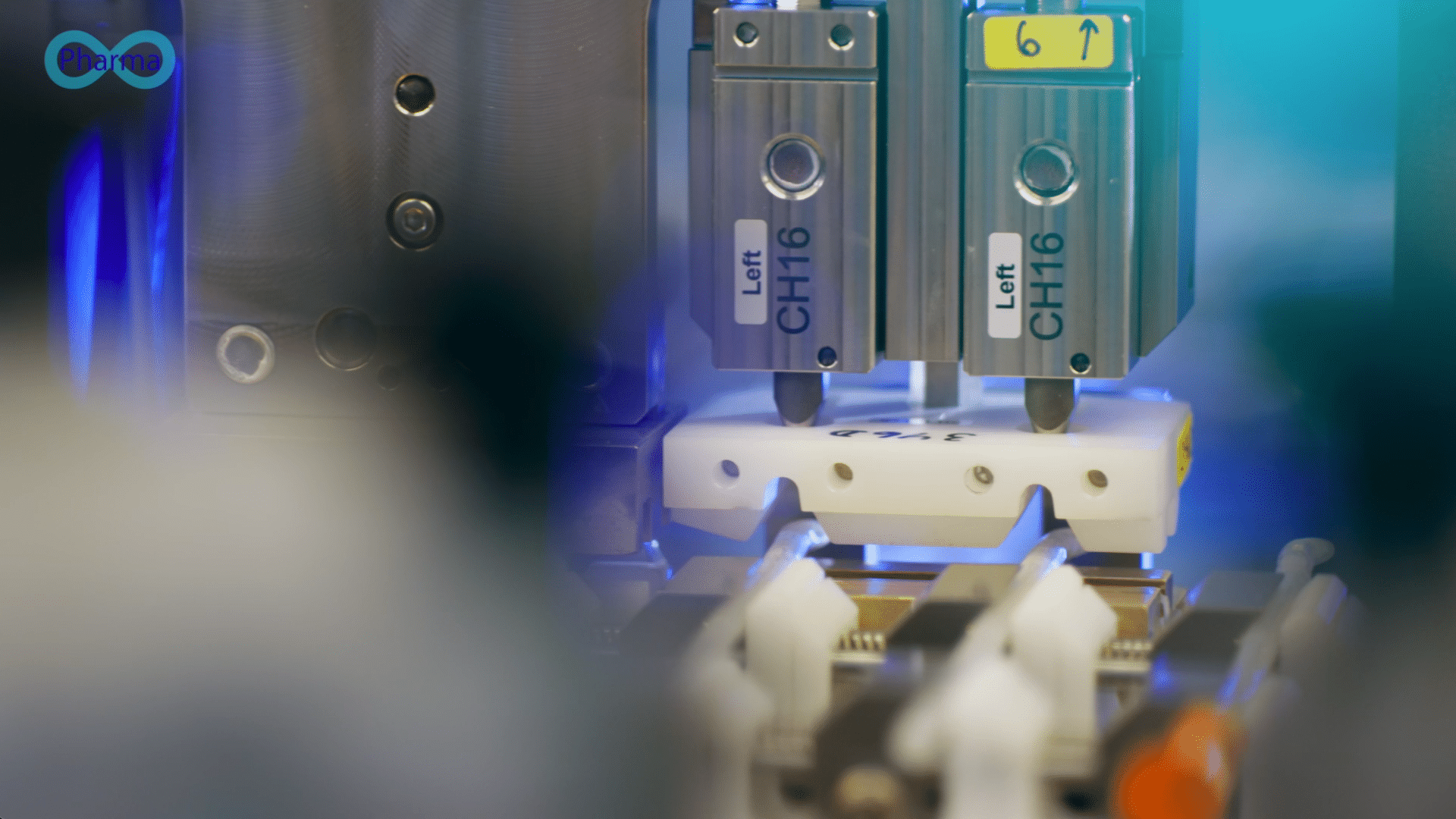

Commissioning is the process where we thoroughly check, test, and confirm that production equipment meets specific standards and performance criteria. Our engineers are experts in this process, carefully examining equipment functionality, validating control systems, and verifying operational parameters. This detailed approach helps to reduce potential risks and ensures that key assets are ready for operation.

Alongside this, Qualification is the essential practice of proving that production equipment and systems perform as expected. Our engineers are skilled in managing Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols. These protocols involve a complete evaluation of equipment integrity and process performance, including the validation of crucial utility systems, to ensure they meet the strict criteria set by regulatory bodies.

Moreover, our specialists are fully aware of the current regulatory frameworks and standards that govern Commissioning and Qualification processes, including the current Good Manufacturing Practice (cGMP) guidelines. They stay updated with changes in regulatory standards, ensuring that our clients always comply with the latest requirements.

In addition to these skills, our engineers have practical experience in carrying out Commissioning and Qualification tasks across a wide range of pharmaceutical facilities. This includes both traditional pharmaceutical manufacturing processes and new technologies in medical device production, ensuring a comprehensive and adaptable approach to compliance.

In conclusion, our consultancy offers unmatched expertise in Commissioning and Qualification processes, backed by the exceptional skills of our engineers. We enable pharmaceutical manufacturers and medical device developers to navigate regulatory compliance accurately and effectively, leading to the production of top-quality therapeutics and medical devices.

We strive to implement simple and operational solutions, and can support the implementation of procedures and training activities that ensure compliance with existing authority requirements and inspection readiness.

© 2025 pharma4ever.com – Designet af Aveo web&marketing

We use cookies to optimize our website and our service.