Production Optimization is a strategic approach where we carefully examine and improve manufacturing processes to increase efficiency and yield while reducing resource use. Our experienced engineers manage this process with precision. They conduct detailed process evaluations, use advanced analytical methods to find inefficiencies, and implement solutions to streamline workflows. This includes assessing critical parameters, integrating the latest technologies, and using process controls to drive continuous improvement.

Root Cause Analysis is a fundamental practice of investigating and identifying the underlying origin of deviations, inefficiencies, or anomalies within production processes. Our specialists conduct thorough investigations, using techniques such as Failure Mode and Effects Analysis (FMEA), Fishbone Diagrams, and 5 Whys. Using their knowledge of process engineering and their skills in material science/analysis, they break down complex issues, pinpoint the exact origins of the problem, and implement corrective measures to fix them.

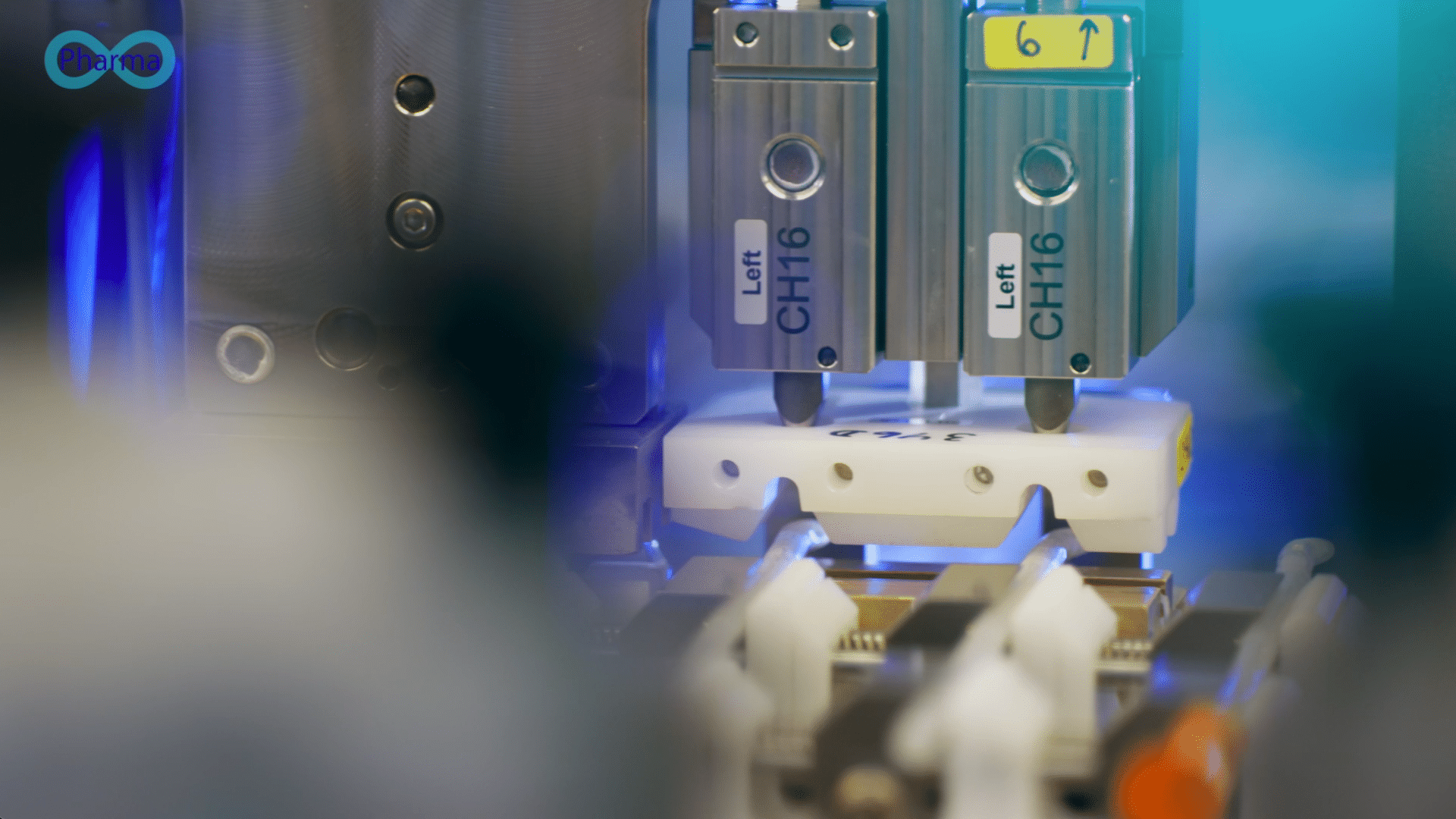

Our engineers also have practical experience in carrying out Production Optimization and Root Cause Analysis initiatives across a wide range of pharmaceutical facilities. This includes both traditional API manufacturing processes and new technologies in medical device manufacturing.

In conclusion, our consultancy offers unmatched expertise in Production Optimization and Root Cause Analysis, thanks to the exceptional skills of our engineers. We help pharmaceutical manufacturers and medical device developers manage their production processes precisely and effectively. This leads to the production of top-quality therapeutics and medical devices, and ultimately improves patient care.

We strive to implement simple and operational solutions, and can support the implementation of procedures and training activities that ensure compliance with existing authority requirements and inspection readiness.

We use cookies to optimize our website and our service.