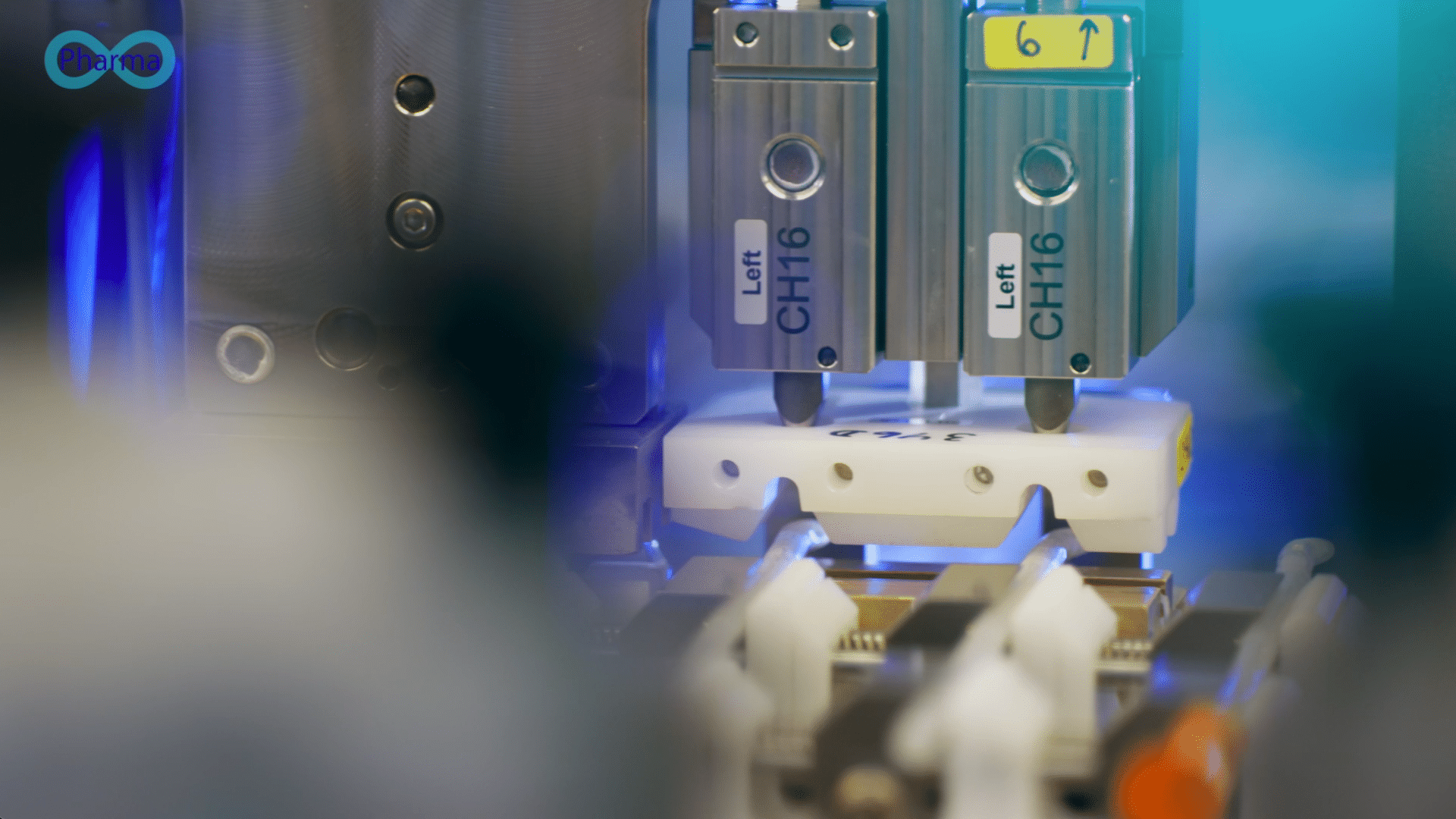

Clean Utility systems comprise a range of utilities such as high-purity water, purified compressed air, and sterile steam, which are indispensable for maintaining the hygienic integrity of pharmaceutical manufacturing environments. Our engineers demonstrate an unmatched expertise in the nuances of designing, commissioning, and maintaining these systems, fully aware of their critical role in ensuring product quality and patient safety.

They leverage a comprehensive understanding of the various grades of water required in pharmaceutical production, from purified water (PW) to water for injection (WFI); and are skilled in the application of advanced technologies such as reverse osmosis, distillation, and filtration to achieve the necessary level of purity. This proficiency extends to the seamless integration of Clean Utility networks with upstream and downstream processes, ensuring a continuous production flow.

Moreover, our engineers possess a keen awareness of the regulatory frameworks and standards governing Clean Utility systems, including but not limited to the United States Pharmacopeia (USP) and European Pharmacopoeia (EP) requirements. They are well-versed in the validation and qualification protocols necessary to demonstrate compliance with these strict benchmarks.

In addition to these core competencies, our engineers exhibit a natural aptitude for troubleshooting and optimizing Clean Utility systems, ensuring their continued reliability and efficacy throughout the pharmaceutical manufacturing lifecycle. This includes the strategic selection of materials, the calibration of distribution networks, and the implementation of robust monitoring and control systems.

To sum up, our consultancy represents an unparalleled depth of expertise in Clean Utility systems, supported by the exceptional proficiency of our engineers. Through our seasoned acumen, we enable pharmaceutical manufacturers to navigate the complexities of these critical systems with precision and efficacy, ultimately leading to the production of therapeutics of impeccable quality, and thereby, advancing the frontier of patient care.

We strive to implement simple and operational solutions, and can support the implementation of procedures and training activities that ensure compliance with existing authority requirements and inspection readiness.

© 2025 pharma4ever.com – Designet af Aveo web&marketing

We use cookies to optimize our website and our service.