Our consultancy is a recognized authority in the field of pharmaceutical manufacturing, with a particular emphasis on Fermentation and Recovery processes, which are integral to the production of Active Pharmaceutical Ingredients (APIs).

Our cadre of seasoned engineers have honed their expertise in both upstream and downstream manufacturing. In the upstream process, they excel in the cultivation of microorganisms that yield the desired therapeutic compounds. They adeptly manipulate and control conditions such as pH, temperature, and aeration to optimize biomass growth and product synthesis.

In the downstream process, our engineers demonstrate proficiency in the recovery and purification of the target product. They are adept at selecting and employing a range of techniques, including filtration, centrifugation, chromatography, and crystallization, to effectively segregate the target compounds from impurities.

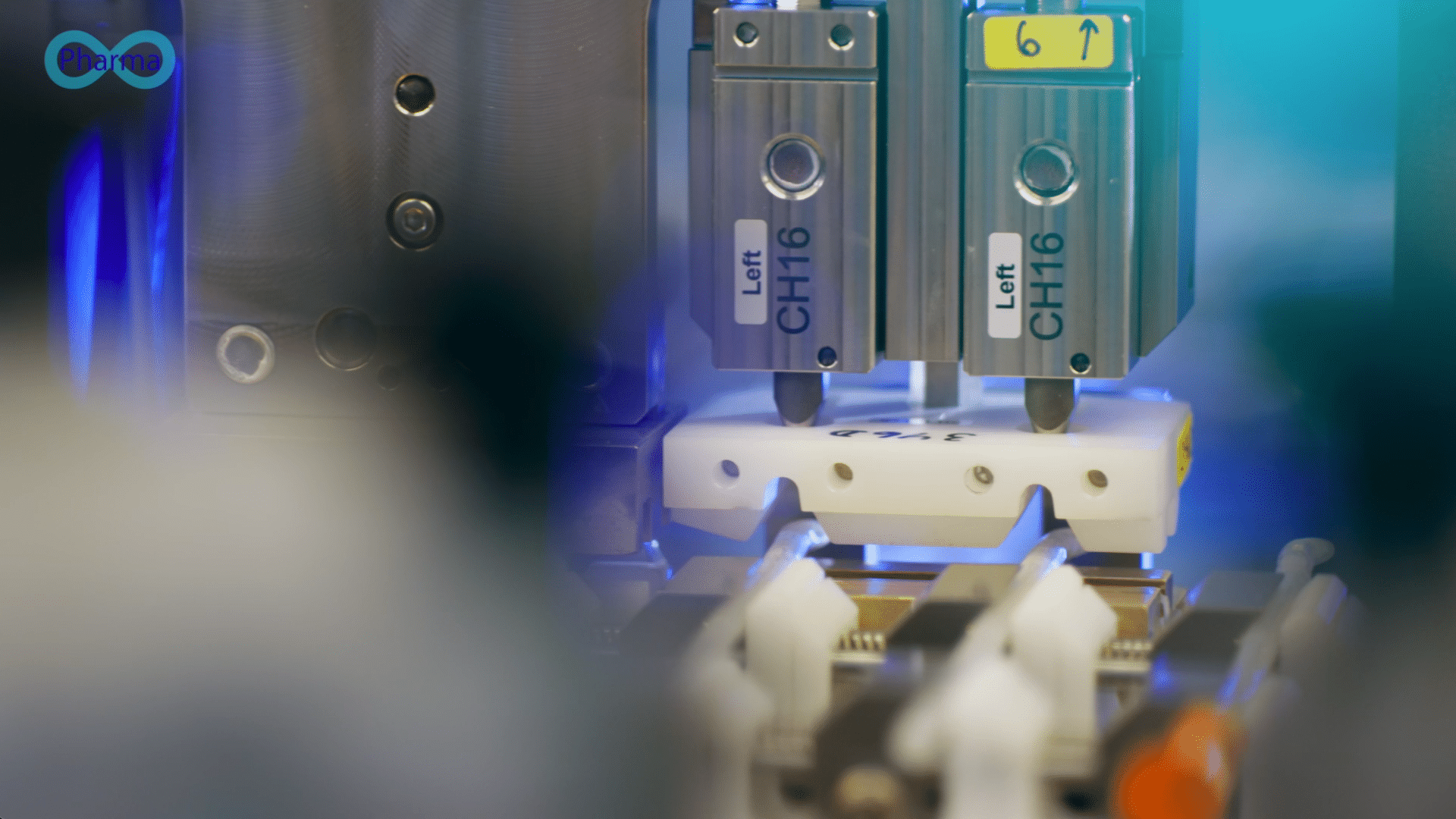

Our team is also experienced in the intricacies of providing process support within Fermentation, Recovery, and Purification facilities, ensuring seamless integration and operational efficiency. They possess a comprehensive understanding of equipment functionality and are skilled at troubleshooting and optimizing critical components ranging from bioreactors to separation units.

In addition to these core competencies, our engineers have extensive experience with Clean Utility systems, which underpin the hygienic integrity of the manufacturing environment. They have expert knowledge in the production, distribution, and storage of high-purity water according to the most up-to-date quality standards.

Furthermore, our consultancy also boasts a robust expertise in Black Utility systems, which cater to the non-potable water needs for ancillary purposes. Our engineers are skilled in overseeing the design, operation, and maintenance of these systems, ensuring their reliable performance within the pharmaceutical context.

In conclusion, our consultancy is uniquely positioned to provide unparalleled expertise in the domains of Fermentation and Recovery, underpinned by the exceptional proficiency of our engineers. Through our seasoned acumen, we enable pharmaceutical manufacturers to navigate these critical processes with precision and efficacy, ultimately leading to the production of superior quality APIs and, consequently, enhanced therapeutic outcomes.

We strive to implement simple and operational solutions, and can support the implementation of procedures and training activities that ensure compliance with existing authority requirements and inspection readiness.

We use cookies to optimize our website and our service.